Technology

With a laboratory and proprietary software, Seccional has already registered a amount of patents that provide to projects and to the clients safety, innovation and technology.

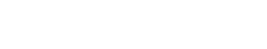

Seccional has proprietary software that allows total security and precision in the dimensioning of its projects, evaluating the stresses and strains in the assembly and operating states, in addition to the ultimate limit state, through finite element modeling. The software validations were carried out in the laboratories of the Federal Technological University of Paraná - Simultaneous Engineering Research Center - NuPES - and Positivo University - Technology Development Center NuTEC.

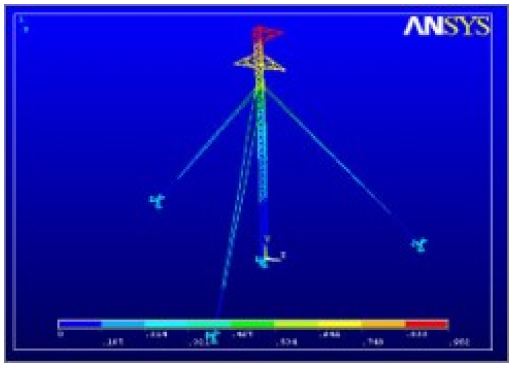

Aerodynamic analysis

Wind tunnel tests were carried out at the LAC Constructions Aerodynamics Laboratory – Federal University of Rio Grande do Sul and at the National Research Council of Canada, which validated the effectiveness and better aerodynamic behavior of the Seccional towers.

Structural tests

To ensure total efficiency and durability, the products are put to the test through destructive tests in laboratories such as the Paraná Institute of Technology - TECPAR and the Central Laboratory of the State - LACTEC, in addition to certified test stations. In this way, it achieves the excellence and guarantee the structures offered.

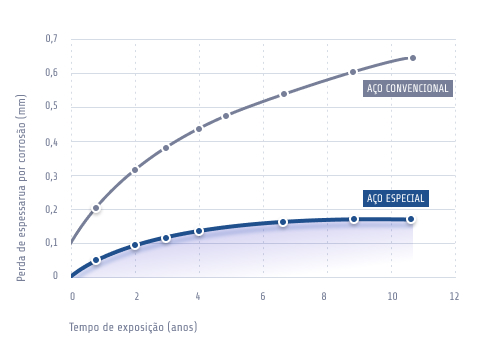

Stronger special steel

Seccional chose to work with the steel of the patinable type, which has a yield limit of 350 MPa, much higher than the conventional steel ASTM A36 with 250 MPa.

This special steel has small alloy contents, such as copper, chromium, phosphorus, niobium, which promote the formation of a compact and adherent oxide film on its surface. This film, called patina, works as a barrier between the steel and the corrosive environment, protecting the structure against corrosion caused by weather changes and aggressive environments.

In addition, the structures are hot-dip galvanized in accordance with NBR 6323. It is the safety of durability that Sectional is keen to ensure.